Premio Alleviates Middle-Mile Logistics Challenges for Autonomous B2B Delivery Truck Company

In this current age of logistics, society has become more normalized to receiving online goods within a 2-day window and expecting online pick-up orders to be fulfilled within hours. This ground-breaking succession of expedited shipping and fulfilment has exposed a major bottleneck in middle-mile logistics. The middle-mile is a critical point where goods are delivered from distribution centers to fulfillment facilities and retail stores. In this case study, we’ll be going over a B2B delivery truck company that is revolutionizing the middle-mile with autonomous technology.

Challenge:

- A reliable in-cabin edge computing solution for their autonomous delivery truck deployment

- Plentiful data storage capacity and full accessibility to store multiple high-resolution video streams

- A rapid data offload procedure to significantly reduce unnecessary downtimes

- Local support for responsive turnaround times and reinforced supply chain navigation/management

Solution:

- Premio’s AI Edge Inference Computer, RCO-6000-CML Series, configured for maximized high-speed data storage and edge performance processing

- Compatibility with EDGEBoost Node featuring 4x hot-swappable NVMe U.2 SSDs totaling 32TB of storage and a PCIe x16 Gen 3 slot

- 10GbE LAN through EDGEBoost I/O to alleviate volumetric data throughput bottlenecks

- CAN Bus for real-time vehicle telematics

- Power Ignition Management for programmable startup and shutdown protocols

Benefits:

- Industry-leading EDGEBoost Data Canisters supporting hot-swappable NVMe U.2 drives to consolidate and simply data offloading procedures

- Premio is strategically located in City of Industry, California with a dedicated sales, engineering, and supply chain support teams

- 30+ years of computing expertise to provide the most optimized and flexible solutions that will exceed and fulfill the needs of end users

The Company

Upon discovering the inefficiencies within the middle-mile and the growing demand for B2B deliveries, this autonomous technology company put their full interest towards developing self-driving delivery trucks. Despite the company being in operation for less than a decade, they have successfully penetrated the supply chain industry by attaining partnerships with a major multinational retail corporation and various Fortune 500 companies across North America. Their autonomous delivery trucks have proven reliable and effective with over 1½ million cumulative miles traveled for sufficient real-world data insights. Currently, the autonomous delivery truck company has deployed over 100 active trucks for various middle-mile applications.

The Challenge

![]()

The self-driving delivery truck company sought out an edge computing solution that can accommodate multiple requirements all within a single ruggedized computing unit. Since autonomous vehicles are estimated to generate several terabytes (TB) of data per day, they required a protocol to rapidly offload substantial amounts of data for minimized downtime. Although the autonomous company could opt in for a NAS solution, they required that the edge system could also provide lite edge AI processing and in-vehicle connectivity in a ruggedized form factor.

Before discovering Premio, the self-driving delivery truck company reached out to an industrial computing provider but wasn’t able to provide the flexibility to meet certain requirements. The solutions provider had data storage capabilities; however, their existing solution wasn’t designed for in-vehicle use. Customization to qualify for in-vehicle deployment was deemed too costly and time extensive. The provider also couldn’t provide the source code due to their proprietary software, limiting data accessibility and control.

In addition to searching for an edge computing solution to meet their demands, the autonomous truck company preferred to establish a long-term partnership with a local United States manufacturer. This significantly reduced the risks of supply chain disruptions and allows for more communicative support if needed.

As reported by CNBC, the trucking industry is currently experiencing a critical bottleneck with the shortage of drivers compared to the overwhelming consumer demands. Integrating autonomous trucking solutions have become a priority to address the industry's pressing demands.

The Solution

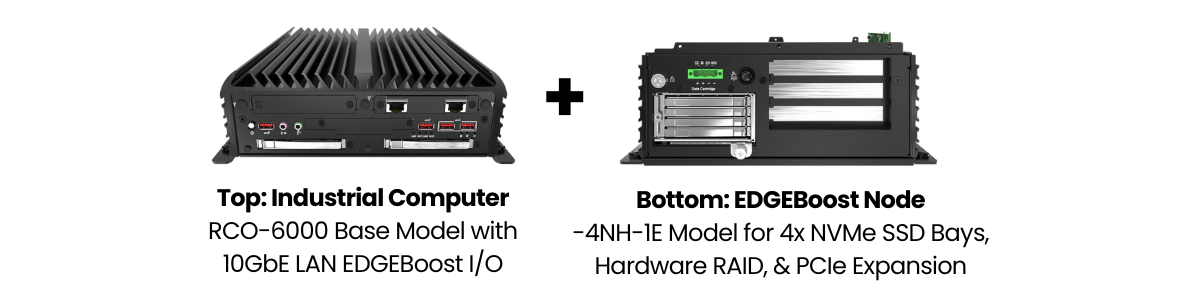

After understanding the deployment requirements of the autonomous delivery truck company, Premio suggested the RCO-6000-CML AI Edge Inference Computer paired with a modular EDGEBoost Node for a unique hot-swappable U.2 NVMe data storage canister. This allowed them to maximize storage capacity, process various edge AI workloads, and deploy confidently for an in-vehicle application.

Driving Real-Time Insights with RCO-6000-CML

The RCO-6000-CML is a high-performance industrial computer that is engineered to streamline edge AI workloads. It is powered by a 10th Gen Intel Core TE 35-watt processor series purpose-built for embedded computing and is constituted under Intel’s embedded 15-year product lifecycle support roadmap. Additionally, the RCO-6000-CML comes fully loaded with IIoT-centric I/O on-board. A few key features that are readily available are: the 16-bit isolated DIO for programmable automation switches and ECC supported DDR4 memory for system failure risk reduction.

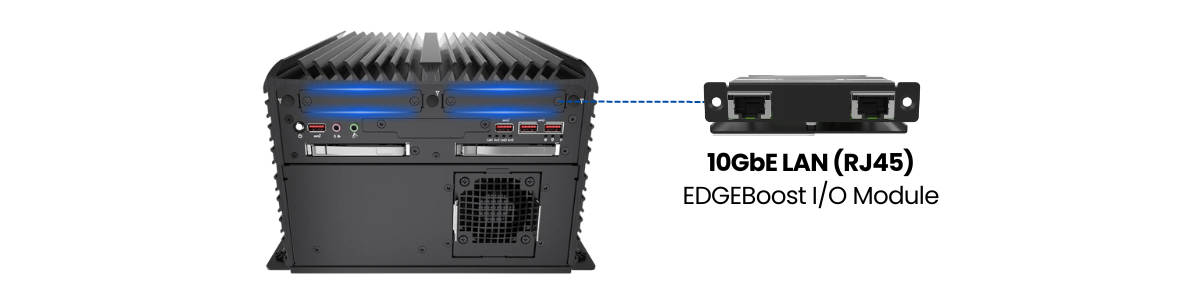

Unique Premio Design: Advantages of EDGEBoost I/O

The autonomous delivery truck company took advantage of an EDGEBoost I/O bracket supported on the RCO-6000-CML by integrating a 2x 10GbE LAN module. This streamlined the process of relaying large volumes of data from high-spec IoT cameras and prevents data stream bottlenecks. For future scalability, there is a secondary EDGEBoost I/O bracket for additional IoT connectivity and/or M.2 performance acceleration.

Unique Premio Design: EDGEBoost Node for Maximized NVMe Storage

A key feature of the RCO-6000-CML is its compatibility with EDGEBoost Nodes technology. Premio recommended the RCO-6000-CML-4NH-1E EDGEBoost Node model to accommodate three key necessities for the autonomous truck company; high-capacity NVMe storage, rapid data offloading, and PCIe expandability. This EDGEBoost Node variant consisted of a hot-swappable EDGEBoost Data Canister (consisting of four individual hot-swappable 2.5” NVMe SSDs), a hardware RAID controller, and an additional PCIe x16 Gen 3 slot for a high-speed network card.

With terabytes of autonomous vehicle data being generated, it is necessary RCO-6000-CML to simultaneously analyze with AI inferencing and store the data in real-time. NVMe technology supersedes the data throughputs rates of traditional SATA, providing the self-driving delivery truck company with an optimized storage workflow for the vast amounts of incoming video streams. Premio suggested this specific RCO-6000-CML configuration because it offers an exceptional 32TB of NVMe storage through a hot-swappable EDGEBoost Data Canister. This EDGEBoost Data Canister holds four individual hot-swap NVMe SSDs and can be taken out as a whole for convenient data offloading procedures. Due to the sensitivity of the data, a hardware RAID controller and the EDGEBoost Data Canister’s locking mechanism is implemented to act as preventative measures against the risks of data corruption, storage drive failure, and tampering.

The PCIe x16 Gen 3 expansion slot within the EDGEBoost Node allows the autonomous truck company to accessorize the RCO-6000-CML with any additional add-on cards needed. From additional networking connectivity to a video streaming capture card, this expansion slot provided them with the flexibility to incorporate any added devices necessary for their project.

Built Rugged, Built Ready for In-Cabin Deployments

The RCO-6000-CML takes a fanless and cableless approach for enhanced durability and hardened reliability at the rugged edge. It features a wide operating temperature of -25°C to 60°C, MIL-STD-810G shock and vibration resistance, wide power input ranges of 9-48VDC, and is UL Listed for safety standards compliance. On top of its rugged features, the RCO-6000-CML also includes in-vehicle support with on-board CANBus and power ignition management. CANBus is critical to accessing real-time vehicle telematics, while power ignition management ensures the system boots and shutdown protocols are attuned with the truck.

The combination of modular EDGEBoost technologies, in-vehicle durability, and real-time edge AI capabilities has proven to satisfy and exceed the needs required by the autonomous truck company. Premio’s RCO-6000-CML has been in operation for over a year with no failures to date and is being deployed in other autonomous projects.

The Benefits

From technical support to mitigating supply chain disruptions, Premio utilizes its 30 years of manufacturing expertise to ensure a smooth, consistent, and communicative system with its dedicated sales, engineering, and supply chain teams. Since both Premio and the autonomous delivery truck company are local to one another, Premio can provide swift turnaround times for immediate support when needed. This transparency and local support were advantageous due to inconsistencies with previous vendors.

As an added benefit of partnering with Premio, we work closely to assist in alleviating certain pain points. A crucial example is when the self-driving truck company was unsure of a data offloading procedure. Initially, they were going to use WiFi to upload terabytes of data in between maintenance protocols, but it was deemed too timely and inefficient. Premio proposed that they leverage the hot-swappable EDGEBoost Data Canisters to seamlessly offload data in a remote datacenter; significantly cutting the data offload downtime from hours to mere seconds. The unique design from Premio’s EDGEBoost Node Data Canisters allows for high-speed PCIe transfer rates, data security with lockable drives, and the ability to hot-swap entire canisters for data offloading.

Additionally, Premio offers a comprehensive portfolio of rugged edge computers ranging from touch panel computers for HMI automation to enable machine vision with industrial GPU computers. The autonomous delivery truck company has taken Premio into significant consideration for future OEM projects that require an industrial computing solution.