Organizations in the manufacturing industry are under more pressure than ever to increase output while maintaining high quality, productivity, and reliability standards. Market demands from consumers and competition from across the globe require nothing less than the most efficient and effective manufacturing systems and processes. Machine vision (MV) is an innovative technology that supplies companies with the ability to become less reliant on traditional human efforts allowing automation to address quality control and minimize flawed operations. MV also increases product output being able to inspect and assemble desired goods and merchandise at exponentially increased rates in comparison to conventional methods once commonly performed by people. Thanks to its many benefits, MV has ever-growing popularity in industries worldwide and is constantly being adopted into manufacturing systems allowing organizations to gain or maintain a strong foothold in their respective markets. In this piece, we’ll provide an understanding of machine vision along with its benefits and explain why they span across so many business types and product categories.

Machine Vision Definition

In the world of industrial business, machine vision is the process by which a computer provides image-based automated inspection for various applications, most commonly for assembly line configurations. The term applies to multiple different levels of technology that have hardware and software products working in conjunction with other integrated systems to extract data from analog or digital images to execute methodical processes with a high level of precision. For example, within a manufacturing environment such as the automotive industry, MV is an integral discipline required in order to employ superior quality control as well as streamlining processes to increase productivity and minimize costly inefficiencies. The assembly of a vehicle requires the coordinated and seamless performance of multiple systems in order to complete their task of constructing their programmed product. A large portion of the overall process is automated in modern high throughput factories and requires great scrutiny to maintain the quality standards required for an organization’s sustained success in an ultra-competitive market.How Machine Vision Works

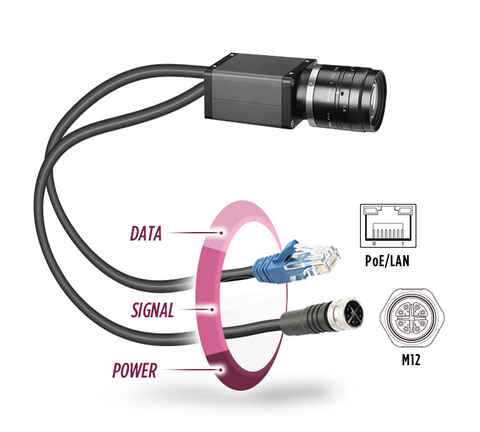

In the process, an image or images are taken of a specific point of the assembly or a component, let’s say an engine piston, with a preprogrammed angle, specific lighting, color or shading, customized magnifications, along with other variables required to determine product quality. The image of the piston can be either processed by the imaging device itself, a feature available with smart cameras or sensors or transferred onward through the processing system to an intermediate unit. The image data is then compared to a preconfigured set of variables within the system to determine a pass/fail judgment of the product. After the determination has been made of whether the piston is accepted or rejected, a preset response for either disposition is initiated to either permit the unit towards the next step in engine assembly or set it aside for further evaluation. This type of procedure is implemented throughout the entire construction of the vehicle. In areas where hand assembly is still required, machine vision is used to reduce and even eliminate human error by examining the work of live personnel. There are several components that must be utilized in order to accomplish the comprehensive and specialized task of machine vision. The image capturing is handled by an imaging device, normally a high-resolution camera, which takes a picture for data analysis. The general usage of 2D imagery is commonplace MV, however infrared (IR) sensors, x-ray images, hyperspectral or ultraviolet (UV) imaging, and laser sensors can also be used for precise measurement recording for 3D imagery as well.

As previously mentioned, in some installations the imaging device is embedded within a processing system operating as a completely independent mechanism and others segregate the imaging process with a separate device connecting to a processing component within the MV infrastructure. Multiple cameras, sensors, or combination of both technologies can be installed for added angle, lighting, and integrity analysis images. Smart cameras and sensors are capable of the extraction of specific data from the captured image initiating an action based on encoded thresholds. They are equipped with the required communication resources needed for connectivity with intermediate units such as a programmable logic controller (PLC). As technology has evolved, these devices also are equipped with PC processing power capable of independent image analysis. In installations where the imaging device connects and transfers data to another component for image inspection, the examination of extracted information can be handled by PLCs or server devices, including embedded and industrial fanless computers such as Premio’s embedded computers. A template of preapproved specifications is used as a baseline comparison with the information provided by the recent image capture to determine variances. The types of recordable data points have an extensive range based on the format of imaging devices employed for any MV structure. This includes pixel counting comparing light and dark pixels, barcode reading, character recognition of text or symbols, blob detection analyzing black colors against gray backgrounds, color analysis, temperature with countless more reportable metric types. Machine vision specialized software programs are installed on computing systems within the system enabling total customization in the configuration of metric measurement and appointed actions based on the results.

Why Machine Vision important?

The impact machine vision systematics have provided to industrial automation has impacted numerous other industries as well. MV has benefitted electronics assembly, food packaging, consumer products, shipping and transportation, retail goods packaging, as well as the medical and pharmaceutical industries. Machine vision technology provides higher quality products, increases productivity and reliability, reduced downtime, and advanced process and inventory control. These values lower equipment and maintenance costs via performance improvement analysis and also lead to savings in labor and production expenses. By being able to provide inspection data analytics at even the microscopic level, organizations fortunate enough to utilize machine vision are able to present quantitative metrics with repeated and sustained lightning speed and accuracy. Studying the information recorded by MV over time aids companies by exposing problem trends, reducing product return rates, and enabling expedient and efficient design changes through software updates to the respective vision system.