What Are Vibration Resistant Embedded Computer?

Vibration resistant or anti-vibration embedded computers are devices that are capable of withstanding extreme environments that expose computer systems to tough shock and constant vibrations. Vibration-proof computers (with SSD) are capable of withstanding vibrations of up to 5 Grms, 10-500 Hz, 0.5 hr/ axis in vibration, and up to 50Gs, half sine, 11ms in shock. Having vibration resistance is extremely important, especially for computers that are deployed in industrial settings where shock and vibration are common and can cause regular computers to fail. As such, vibration resistant embedded systems are preferred for deployment in such environments.

What Are Some Popular Embedded Applications That Experience Shock And Vibration?

Understanding the environment where you are deploying a systems plays a crucial role in the success of your application. This is so because industrial applications often require deployment of systems in harsh environments that experience wide temperatures, dust particle ingress, water exposures, tough shock, and constant vibration. Deployment in an extreme environment can involve all of these threats that can easily cause system failure for regular, consumer grade desktop computers. That is why vibration-proof industrial computers are required for mission-critical applications where devices are exposed to challenging conditions, such as shock and vibration. Here are several applications that utilize vibration-resistant computers due to the high exposure to shock and vibration.

1. Railway System

Railways are one of the applications that expose embedded computers with constant vibration. The vibration in the railway is varied depending on the rail, speed, vehicle type track quality, and much more. Based on the International Union of railways report, the ground-borne vibration where the train interacts with the track produced a vibration in a frequency range of roughly between 1Hz and 100Hz. Thus, there are various vibration-resistant computers are utilized on railway solutions.

Moreover, industrial fanless computers are certification-ready for railway usage. Electronics that are installed on a train must meet a certain standard for environmental, EMC (electromagnetic compliance), ESD (electrostatic discharge), power surge, power supply, shock, vibration, and other factors that could appear during deployment. With the compliance of EN50155 conformity for railway applications, the industrial computers have been tested and validated for their safety and reliability during railway deployments. This certificate is crucial to ensure the performance of the devices are capable of running 24/7 for 30 years (around 250,000 hours) without compromising the safety and reliability of the applications.

2. In-Vehicle Solution

Intelligent transportation, fleet management, and autonomous vehicles are some of the in-vehicle solutions that require a vibration-proof computer. A car vehicle can produce vibration around 1Hz up to 25Hz during normal operation. This is where anti-vibration embedded systems should be used as they are capable of withstanding shock and vibrations, but also are capable of withstanding extreme temperature, dust ingress, and water exposure. The multiple extreme environment condition that exists in one solution.

3. Mining Industry

Vibration-resistant industrial computers are used to tackle the riskiest threats and operations for surface and underground mining applications. Shock and vibrations are common environmental elements in mining due to the use of explosives for excavation and extraction. The ground-borne blasting vibration can reach around 2.5Grms, 1Hz to 300Hz around the explosion location. Thus, vibration and shock-resistant industrial computers are implemented instead of a standard computer that will quickly fail in this situation.

4. Military

Military operations also require the most rugged devices to guarantee the mission's success amid mission-critical combat situations. From heavy-weight vehicle to explosive gunfight, the DoD (department of defense) use a Military standard such as the MIL-STD-810G to ensure only the most robust, rugged, reliable, and durable technologies are the one operating in a combat situation. Vibration-proof embedded computers have passed the MIL-STD-810G qualification in shock and vibration, which indicates the robust design and architecture of vibration resistant embedded computers. Vibration resistant computers go through a series of test to ensure shock and vibration levels meet the MIL-STD-810G standard. For example, computers that can withstand 50G shock and 5GRMS vibration comply with the MIL-STD-810G standard.

Can Vibration Damage Computers?

The short answer is yes, vibration can quickly damage a computer and lead to a system failure. Standard computers equipped with HDDs (hard disk drives) are even more prone to damage even when exposed to the slightest amount of shock and/or vibration. This is due to the mechanical disk component that moves very quickly to read and write data for storage. Any moving parts in a computer are a potential point of failure against shock and vibration. The spinning disk in an HDD can spin extremely fast from 1200 RPM up to 15000 RPM, which can very easily damage when are exposed to shock and vibration.

Other moving parts like the fan are also a huge failure point that can jeopardize the computer performance. Moreover, the desktop commercial PCs are built with cheap plastic and thin aluminum materials that are not meant to protect the internal component from extreme environments. On the other hand, industrial-grade computing solutions are tested to ensure reliability even in the most challenging environmental conditions. Also, vibration-proof industrial computers are built extremely rugged and robust to withstand extreme environments including touch shock and constant vibrations while maintaining their durability, reliability, and longevity.

7 Indicators Of A Robust Vibration Resistant Embedded Computer

1. Fanless Design

Vibration-resistant embedded computers implement a fanless design that utilizes passive cooling to effectively dissipate heat from the internal component to the external environment. The heatsink conducts heat from the hottest part of the computer which is the CPU and dissipates it through the external enclosure for cooling. The heatsinks are crafted from highly conductive material, usually aluminum and copper, which is very efficient in conducting heat. Fanless design is one of the indicators to look out for when choosing the best vibration-resistant computer.

2. Cable-less Design

Reducing as many moving parts as possible in a computer can increase its durability against tough shocks and vibrations. Cable-less design not only increases vibration resistance, but also prevents cable routing & cable matching problems, and prevents cabling signal degradation and latency. By implementing cable-less design, the computer can increase its durability, reliability, and longevity.

3. SSD Storage

One of the easiest components that can be damaged by shock and vibration is HDD storage due to the fragile spinning disk. When the disk is spinning really fast, a small jitter on the computer might cause data corruption and some error functions that increase downtime risk. SSD or solid-state drive, do not rely on any moving parts. SSD store its data on a series of NAND chips that retain the charge without the need for a power source. Using chips instead of spinning disks makes SSD extremely rugged, which is great for vibration-proof embedded systems. Moreover, SSDs are much faster, compact in size, and energy-efficient compared to HDDs.

4. Industrial Components

The most robust vibration-proof industrial computers focus both on advanced design and premium materials. Great vibration-resistant computers are made out of industrial-grade components from their resistors, capacitors, power chokes, PCB, I/Os, and more. Vibration-proof PCs are constructed with industrial-grade components for industrial-grade performances that ensure uptime and avoid downtime.

5. One-Piece Chassis

To ensure the vibration industrial computer can withstand the toughest shocks and vibrations during deployments, the outer enclosure is made out of one-piece chassis. The enclosure is a single mold that is made from extruded heavy-duty metal that provides a robust structure for extra protection. The one-piece chassis also works as a heatsink that dissipates heat from the internal component. With fewer joint parts, gaps, and screws, the sealed housing can prevent dust ingress and increases the level of protection during deployments.

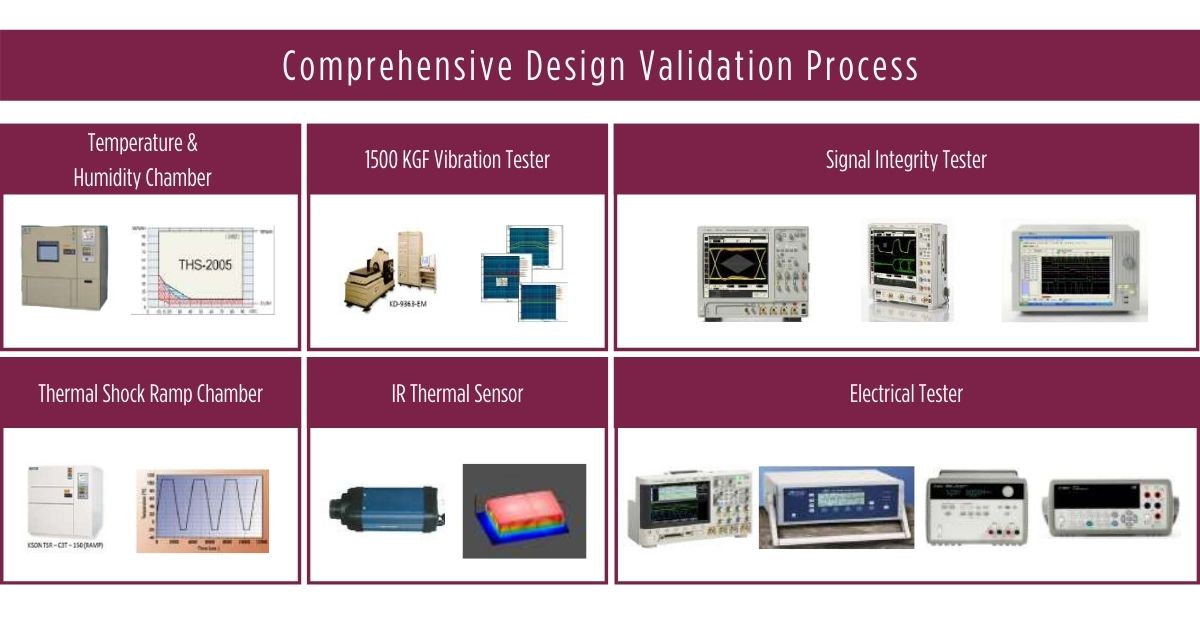

6. Comprehensive Test and Validation Process

To guarantee a world-class quality of an industrial computer that is vibration resistant, the computer is tested and validated in detail for reliable MTBF performances. The test and validation process are conducted in a reliable testing facility that tests the devices for every possible environment case to its limit.

For vibration, the computer is tested on a random vibration test simulator that can simulate realistic situations by imitating a real environment behavior that involves vibration. For example, in a military application, during a combat situation, only simulating constant vibration for a set period of time will not represent the real environment during combat. Constant and multiple frequency, amplitude, and shocks are generated by the machine to test the capabilities of the computer to withstand shock and vibration in a real-life scenario.

7. Following the MIL-STD-810G Standard

MIL-STD-810G is a standard created by the DoD (department of defense) to ensure the quality of devices used in a combat situation are completely rugged, robust, and reliable during deployments that involve tough environmental challenges in a combat situation. If your computer complies with the MIL-STD-810G test and validation standard in shock and vibration, it is one of the indicators that help to ensure the quality of your vibration-resistant computer. However, the MIL-STD-810G compliance claim can be misleading. It is important to make sure to review the test process and procedure manufacturers use to ensure MIL-STD-810G compliance.

Learn More About MIL-STD-810G Standard for Military Grade Industrial Computers