Edge computing is when embedded systems are deployed to process data locally at the source of data generation in real-time. Industrial and outdoor deployments pose new challenges where devices aren’t only required to have powerful compute power, but also need to withstand extreme environments. Extreme environments can involve high heat, low heat, hard shock, constant vibration, water exposure, and dust exposure. For standard desktop computers, water and dust exposure are among the most threatening factors capable of causing instant failures and permanent damage. Therefore, for outdoor deployments, organizations should consider only deploying IP-rated embedded computers, such as an IP 67 embedded system to ensure reliability, durability, and longevity against extreme water and tiny dust particle exposure. Furthermore, in this blog post, we are going to discuss some options to tackle the water and dust particles problem and explain how IP67 embedded systems strive for outdoor industrial deployments.

Two Simple Solutions for Protection Against Dusty and Wet Environments

1. Utilize NEMA Enclosure

2. Deploy a High IP Rated Device

What is NEMA enclosure?

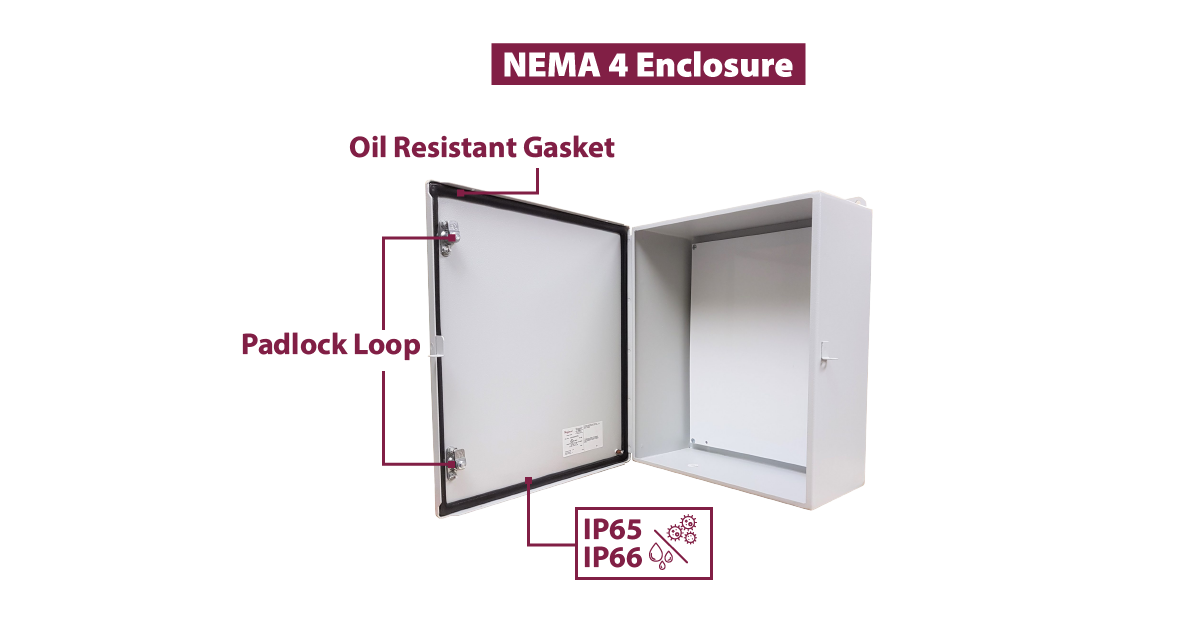

A NEMA enclosure is an enclosure standard that has been adopted for various ratings of electrical component enclosures that are commonly used in industrial applications with harsh environments. NEMA is the abbreviation of the National Electrical Manufacturers Association which is the standard for electrical enclosures in North America. That said, NEMA enclosure provides a case for protecting computers from external exposures, mainly from water and dust ingress.

Among the various types of NEMA enclosure, NEMA 4 or NEMA 4X is the most popular enclosure for outdoor embedded computing applications. NEMA 4 protects computer systems against dirt, rain, sleet, windblown dust, ice formation, and splashing water, which is equivalent to deploying an industrial computer that is IP65/IP66 rated. Some NEMA enclosures also can be coated with additional anti-corrosion material to protect them from rust. However, a standard NEMA enclosure should suffice to protect an industrial computer from the challenging environmental factors listed above.

Why NEMA isn’t enough?

Although choosing a NEMA enclosure for an outdoor computing solution can be pretty straightforward, there are several disadvantages and compelling reasons why NEMA enclosure might not be the right solution for extreme environments solution.

Firstly, due to the many kinds of NEMA enclosures that make it complicated and frustrating to choose the right match for your application. NEMA enclosures come in myriad combinations with different shapes, sizes, materials, ratings, mountings, and additional features like external coating. It can be confusing to simply choose an all-in-one solution for your applications, and more importantly, a wrong decision can cause leaks that cost the company a huge potential downtime expense. NEMA enclosures can be expensive as well, especially for customization request that needs unique sizes, external coating, different materials, mounting options, and more can easily stack up the overall cost with an unnecessary request.

Secondly, installing a NEMA enclosure can be tricky, you sometimes need a drill to install the enclosure and to modify the I/O inputs. This can be a struggle, especially for a harder material. Moreover, at the edge, many space-constrained applications make it difficult for the bulky NEMA enclosure to fit into the tight spaces. Even if they fit perfectly, you still need a gap for opening and closing the enclosure during installation, modification, or maintenance. Need to note that if you use a non-waterproofed computer, you want to be extra careful when you opening the enclosure so the rain won’t reach the computer inside the enclosure.

Moreover, there are additional risks of human error that can jeopardize the application, for instance, if the user didn’t properly install or close the enclosure, water and/or dust can make their way into the PC, damaging it. That said, there are too many risks and struggles that appear from utilizing NEMA enclosure and make it much simpler to utilize a high IP rated embedded system for your applications.

What is IP Rating?

Ingress protection rating or in short IP rating is a standard that measures and validates a system's capability to prevent tiny water droplets and dust particles from making their way into an electronic device. An IP rating consists of two digits that represent the protection level from dust and water particles. The first digit indicates the degree of protection from tiny dust particles and the second digit indicates the degree of protection against tiny water droplets.

What IP67 Indicates?

IP67 embedded systems are capable of protecting the inner components fully from dust particles and full immersion in 1-meter depth water for up to 30 minutes without affecting the system. Dust-tight and waterproof IP67 embedded systems are perfect for industrial deployments in challenging environmental conditions. With IP 67 rated computer, there is no need to use a NEMA enclosure to protect external exposure and the applications are capable of performing within space-constrained deployments.

The Built Quality behind IP67 PC

1. Fanless Design

IP67 computers employ a fanless design within their architecture which utilizes passive cooling to dissipate heat from the internal component to the enclosure that works both as a rugged chassis and a heatsink, dissipating heat into the air surrounding the system. . By using a fanless design, Premio has eliminated some of the issues associated with using fans to cool down systems. Instead, IP67 industrial rugged PCs are implementing heatsinks on their PCH (platform controller hub) and CPU (central processing unit) to cool down the hottest component of the computer. These heatsinks are made out of highly conductive materials (aluminum and copper heat pipes) that are very effective for dissipating heat. After all, without venting holes for the fan, it is much easier to create waterproof and dustproof IP67 computers.

2. One-Piece Enclosure

IP67 rugged embedded computers are even more durable compared to many NEMA enclosures and standard desktop PCs on the market. The chassis is made out of extruded aluminum and heavy-duty metals that are molded into a one-piece enclosure, making the IP67 industrial PC strong and corrosion-resistant. Rather than made out of connected parts, a one-piece enclosure exponentially increases the device’s reliability, durability, and longevity. Moreover, the IP67 rugged PC is airtight which increases ingress protection without any gaps and screws to attach the enclosure.

3. M12 Connectivity

IP67 rated industrial computers are equipped with M12 with PoE (Power over Ethernet) connectors capable of delivering both data and power over a single cable. Having M12 connectors contribute to the ingress protection of dust and water. M12 connectors are incredibly reliable due to their dust and water-tight properties that are easily installable and designed to reduce the risk of failure. M12 connectors are rated at a minimum of IP67 up to IP69K for ingress protection rating. With a compact size of only 12 mm in diameter, M12 cables are filled with a 360˚ EMI (electromagnetic interference) shield that secures the connections around other electronic devices.

Real Applications of IP67 Computers

High IP rated computers are best used to tackle constant exposure to water and dirt that might compromise the device's performance if they are not properly sealed. Industries such as mining, automotive, food manufacturing, beverage processing, healthcare, outdoor kiosks, and more are constantly facing dust exposure, heavy rains, and extreme washdowns. This is why you need a tightly sealed IP67 embedded system for your edge applications.

Other Advantages of IP67 Industrial Embedded System?

IP67 extreme rugged industrial PCs aren’t just equipped with tight ingress protection, they are also rugged in other areas to provide an all-in-one solution for industrial application deployments amid extreme environments.

1. Wide Temperature

Due to the high-conductive heatsinks and one-piece chassis that work as a heatsink, IP67 embedded PCs are able to perform within the extreme cold and hot environment ranging from freezing -40℃ up to scorching hot 70℃ environments while maintaining their tight IP67 sealing.

2. Shock and Vibration Resistance: Cable-less Design

IP67 rugged industrial PCs are also resistant to tough shocks and constant vibrations that comply and even surpasses the MIL-STD-810G standards for shock and vibration resistance. IP67 extreme industrial computers are capable of sustaining 50Gs of shock, Half sine, 11ms (with SSD) for shock, and 5 Grms of vibration, 5-500Hz, 0.5hr/axis (with SSD) for vibration. Thanks to their fanless design, cable-less design, one-piece design, and industrial-grade parts, IP67 industrial PCs are extremely tough.

3. Power Protection

When embedding IP67 computers to an external system, having the ability to control voltage inputs is essential in prolonging the hardware longevity. High IP rating embedded systems are equipped with OVP (over-voltage protection), OCP (over current protection), and a wide range of voltage power input. The OVP feature will automatically cut power input more than 55V to avoid burning the internal components and the systems are compatible with inputs ranging from 9V up to 48V for deployments in different applications. Moreover, the power ignition management systems make the system very versatile for deployments in the automotive industry.

4. Easy Installation and User Friendly

IP67 rated rugged computers are configured with wall mounts to make them universally available to be mount in any configuration possible. Additionally, with a one-piece design, IP67 embedded systems can be easily disassembled and adjusted without any special equipment.

5. Legitimate Testing and Validation Process

To guarantee the reliability, durability, and longevity of the system performances amid extreme deployments for an extended period, IP67 embedded systems went through a rigorous testing and validation process. Every type of IP67 embedded system is tested and validated in a reliable comprehensive testing facility for run validation processes such as in a temperature and humidity chamber, 1500 KGF vibration tester, thermal shock ramp chamber, IR thermal sensor, signal integrity tester, IP rating tester, and electrical tester.

IP67 Alternatives

To accurately match the application solution based on personal requirements, there are other great IP67 alternatives for high protection against tiny dust and water particles. IP65 embedded systems are also a great alternative for less extreme outdoor applications. Or utilizing the hybrid models of high IP rating models with NEMA enclosure if you need to add extra guarantee for the systems applications.