The industrial Internet of things (IIoT) that has enabled the rise of the data-centric fourth Industrial Age is founded on the principle of exhaustive, unimpeded data transmission. Connected systems have had to leave behind wired setups for wireless systems to relay floods of data across facility spaces. A number of wireless technologies have been deployed in various sectors — 4G-LTE, 5G, Wi-Fi — and each brings unique strengths to a variety of applications, though they can prove unwieldy to implement and maintain at the scale required for connected factories. Bluetooth systems — namely Bluetooth 4.2 and later — are optimized to leverage the strengths of other connected technologies in a more limber presentation to suit the challenging conditions found in industrial facilities.

Bluetooth technology is informed by several protocols unified by a single specification set. The Specifications are managed by the Bluetooth Special Interest Group (SIG). The SIG ensures that Bluetooth-enabled devices will be universally connectable with each other, regardless of geographical origins of the technology being paired.

Industrial facilities undertaking digital transformations are rapidly adopting Bluetooth devices to accelerate Industry 4.0 efficiencies. Industrial Bluetooth sensors and data nodes quickly and easily paired with deployed industrial PCs process vast amounts of data in real-time to gain immediate actionable insights that improve safety, drive automation and refine processes to reach greater productivity. In response to the expanding industrial applications, Bluetooth 5 was released with IoT utility in mind in the shape of improved data speed and transmission range options.

So integral is Bluetooth’s role to the swelling Industry 4.0 that the SIG predicts Bluetooth device shipments to the industrial sector to nearly triple by 2024 with 335 million. But what is it about Bluetooth technology that makes it ideal for connecting facility systems?

Streamlined Setup

For starters, Bluetooth devices require far less setup effort than competing wireless technologies — most implementations requiring a single button push to pair devices. Many other wireless deployments have a more complicated setup that can result in greater communication range, speed and bandwidth — enhancements often of an unnecessary degree for industrial spaces. These spaces can host hundreds or even thousands of wireless data endpoints, and a frictionless setup ensures minimal downtime to achieve the needed scope of connectivity.

Bluetooth specifications deliver universal interoperability to devices deployed in any global region regardless of regional industrial standards. Furthermore, its serial port profile ensures smooth integration with existing industrial systems.

Reliable Performance

Other bulky wireless technologies can deliver performance akin to high-speed hardwired connectivity. Bluetooth’s short, efficient bursts of data, however, better fit the application needs in the industrial setting. Bluetooth broadcasts weak 1-milliwatt data packet signals over the 2.4 Ghz industrial, scientific and medical (ISM) radio frequency band. The bandwidth is limited and heavily trafficked, but features in Bluetooth specifications make it more than adequate for industrial applications.

More recent releases of the Bluetooth standard boast Forward Error Correction (FEC) algorithms that ensure the integrity of the data communicated. By including redundant information bits in transmissions, FEC effectively detects and repairs data errors.

Newer Bluetooth implementations also allow positioning detection for paired devices. Bluetooth devices utilizing positioning detection can monitor device location and track facility assets with far greater precision than other wireless technology options.

Scalable Connectivity

Bluetooth was originally designed to support no-hassle point-to-point, 1:1 broadcast communications. In its simplest deployment, a single “master” device can communicate with up to seven “slave” devices to form a piconet. Two or more piconets can be connected to form a scatternet. Scatternets are made possible when a device simultaneously serves as a master in one piconet and a slave in another. Improvements of the Bluetooth technology have further increased the communicative scope and scalability that has accelerated Industry 4.0.

Bluetooth 5 can operate on a self-healing, low-power mesh network that allows the rest of the network to continue functioning in the event one device fails. Mesh networks provide many-to-many device communications between more than of 32,000 devices. The network is decentralized, which allows nodes to communicate directly with one another. Mesh networks connected with an onsite rugged industrial PC provide a highly-reliable low-latency data processing solution for refining facility operations.

High Immunity to Interference

Industrial facilities can host thousands of transmitting data nodes and equipment that can emit torrents of interference that can cripple most wireless technologies. Bluetooth, however, is the standalone primed to function on the “noisy” industrial space.

Bluetooth 1.2 featured frequency hopping spread-spectrum (FHSS) to pseudo-randomly alternate between 79 frequencies in their range 1,600 times per second to greatly reduce the effects of interference. Devices deployed with adaptive frequency-hopping (AFH), identify channels where other wireless devices would conflict with the signal transmission, allowing them to further avoid interference.

Low Power Consumption

Many industrial devices and sensors need to maintain “always-on” performance, increasing the power demand greatly as the industrial facility grows its data node population. Ubiquitous Bluetooth Low Energy technology is optimized to deliver virtually the same communication range as Bluetooth Classic with a far lower power consumption than other connected solutions, reducing operational costs considerably.

Bluetooth’s energy efficiency and simplicity come with a tradeoff of having a smaller communication range than other wireless deployments. The Bluetooth range, however, has seen significant improvements with newer releases, granting greater distance by modulating the size of the data transmitted. The flexibility allows facility operators to fine-tune Bluetooth deployments to meet their specific data load/range needs for their spaces. By deploying rugged industrial PCs close to the data nodes, the Bluetooth connected systems reduce communication distances enabling transmission of larger data packets for richer system insights.

Resistance to Cyberattack

Industry and critical infrastructure facilities are favored targets of attack for malicious actors. They are chosen for the vast selection of vulnerabilities exposed when bringing traditionally air-gapped legacy equipment online, and for the same equipment’s potential to generate significant negative consequences if compromised. Bluetooth technology features several protections eliminating openings for outside manipulation.

From the outset, Bluetooth’s shorter transmission range requires devices to have close physical proximity to pair and communicate. This locational “limitation,” however, prevents remote cyberattacks from outside the target device’s range. If a party is somehow able to get within range to launch an attack on a Bluetooth device, the AFH interference measure ensures anyone attempting to intercept signals would need to be privy to which channels are being used for each packet — information only known by the transmitting and receiving devices.

Devices adhering to newer Bluetooth standards have further measures that prohibit unauthorized parties from interfering with communications. Messages sent throughout mesh networks are encrypted and authenticated to combat man-in-the-middle cyberattacks, brute-force decryption and outside signal manipulation.

Bluetooth for Industry 4.0: Premio’s Rugged Industrial PC Solutions

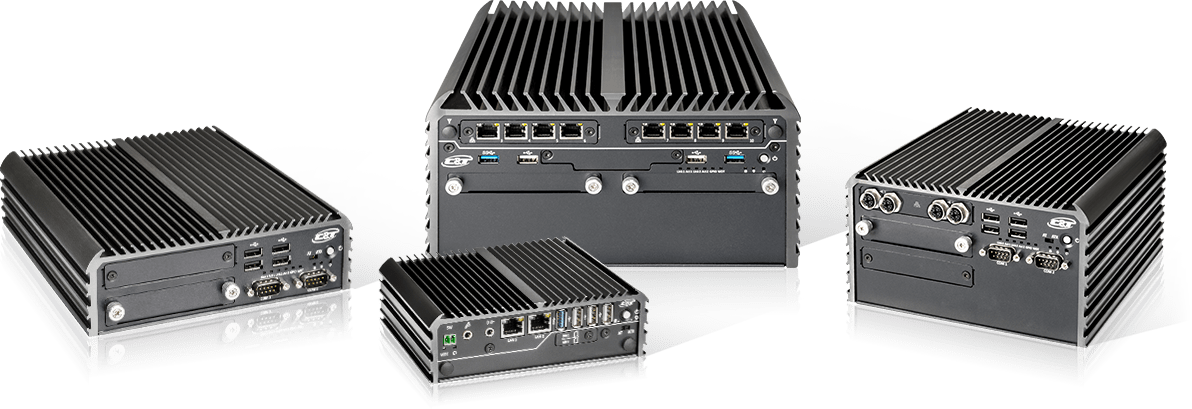

Premio’s purpose-built industrial PCs deliver robust compute power into facility environments with challenging or volatile conditions. The rugged fanless, cable-free devices are rated to sustain elevated levels of abuse for always-on performance with extended MTBF.

Premio industrial PCs have several connectivity options for mobile, remote and wireless local deployments. With secure, reliable Bluetooth technology, the PCs aggregate and process large volumes of data from paired devices and sensors, while TPM-secured Wi-Fi and 4G/LTE options enable safe transmission to offsite networks and cloud resources for further processing and storage.

Bluetooth IIoT nodes paired with a local industrial PC give facility operators a safe, latency free transition to join the fourth Industrial Revolution. Simplicity of integration grants greater flexibility in the scale of deployment and scope of connectivity that suits every facility’s unique requirements.