Video Transcript:

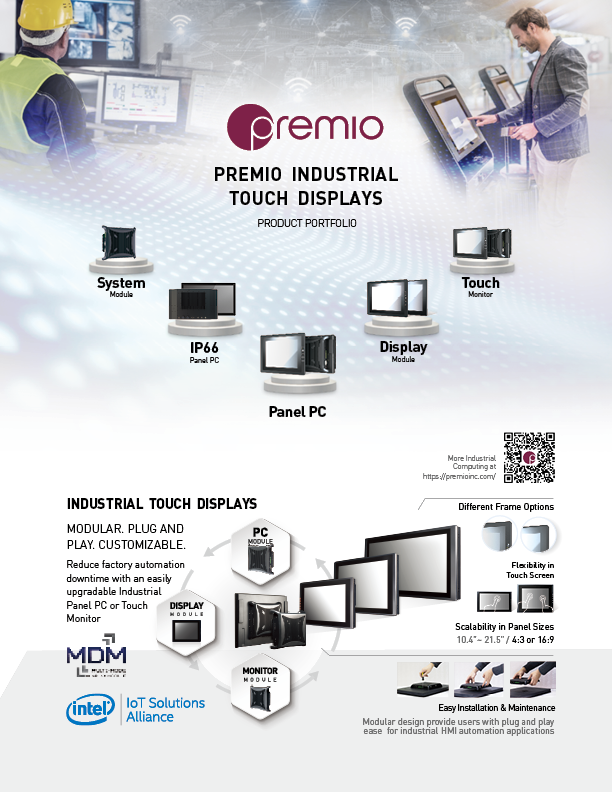

Eliminate detrimental downtime and increase scalability with an innovative industrial panel pc or rugged touch monitor featuring our patented modular MDM technology. Leverage flexible and customizable features from display sizes ranging from 10.4” inches to 21.5” inches, a choice in the most popular touch technologies, as well as deployment options either in a thin or standard frame for your industrial automation deployment.

The modular “MDM technology” provides easy and upgradable pc modules that can mix and match with our industrial VIO series displays all without replacing the entire device. Specifically designed for industrial automation and in-line factory H-M-I displays, the modular design provides complete freedom during installation and maintenance. The key benefit for modular technology in automation is its ability to reduce malfunction downtime and provide next generation computing upgrades in no time.

Premio Industrial Touch Display and PC Module features rugged IP65 rating for water-resistance, wide-temperature support for industrial environments, resistance to shock and vibration, and power protection to ensure reliability

Contact us to learn more our how MDM Display technology can scale with your Industry 4.0 deployments today!

What is an HMI or Human Machine Interface?

HMI in the world of manufacturing and industrial automation is defined as Human Machine Interfaces. In simple terms, these are display interfaces that assist with better productivity and operational efficiency, by streamlining important function between humans and automated machines. Process engineers use HMIs with dedicated supervisory control and data acquisition software (SCADA) to control complex manufacturing operations and processes either manually or remotely. In a technological landscape, SCADA systems help industrial operations maintain efficiency, provide data processing, and communicate issues. Popular HMI infrastructure setups are common in industrial control panels and programmable logic controllers (PLCs) because it provides technicians the ability to choose and determine a pre-planned result from the machine and its application. These type of management hubs control critical processes and information flows which, usually is a complex network of sensors, alarms, and on/off functions. HMIs in combination with PLCs are common in industrial automation applications in markets dealing with oil, gas, water, electric, mining, and in-line inspection manufacturing.

Common Use of HMI in Manufacturing:

- Turn on/off industrial sensors, valves, alarms

- Display and monitor Critical Data in Dashboards

- Control IoT machines and devices

- Push repots, messages and KPIs

- Turn mechanical operations into visual processes to diagnose problems

As newer advances in technology provide scalable solutions that improve operational efficiency and maximize business profitability, digital manufacturing demands and its goldmine of aggregated data is driving transformations. This transformation is becoming known as “Industry 4.0”, where the value lies in data and predictive insights to prevents problems. Machines are no-longer static and are connected through networks of IoT and are helping humans on factory floor make better and predictive decisions. HMIs, specifically touchscreen computers, all-in-one computers, and Panel PCs are high in demand for streamline automation operations. The demand calls for faster processing, more storage capacity, and wireless connectivity in a world where data is driving decisions for better outcomes.

Why Traditional HMIs Need to be Upgraded for IoT?

Many industrial control processes originate from legacy technology and infrastructure from its early stages of inception. Especially in industrial manufacturing, many of the control panels and PLCs were highly specialized and customized for complex functions in specific operations. For example, the functions and management of an oil/gas process control is very different than a water treatment plan. This level of a customization by design is prevalent in many current industrial markets which, eliminates flexibility and requires multiple access points for process control management. Another factor in customization requires redundancy for critical points of failure. For example, if HMI panels fail, they will need to be swapped out with a spare unit to prevent downtime and a loss to productivity. With that said, a major disadvantage from traditional HMIs and their logic controllers is the lack of flexibility and interoperability in an intricate network of complex machines. Enter IoT and its enormous potential for businesses to make better decision from real-time data and insights.

Better Option to HMIs: Industrial Panel PCs and All-in-One Touchscreen Computers

Industrial Panel PCs and All-In-One Touchscreen computers are becoming dominant interactive solutions in HMI deployment for industrial control systems. A key driving force for panel pcs is its scalable “All-in-one” functionality and industrial reliability. Overall, computers are viable solutions to manage sequential tasks and have the capability to control multiple functions efficiently. Once combined with the right hardware and software, computing solutions like panel pcs are much better than static HMIs. Today Panel PCs are embedded in a digital world that offers maximum versatility and feature the latest in touch technology (PCAP and Resistive), Industrial grade LCD panels with high-nit brightness, and resistance to harsh environmental factors (Wide-temperature, IP Water Resistance, and shock/vibration). In addition, the best panel pcs designs use fanless cooling technology that increases reliability and longevity, reducing the possibilities of failures. But what really makes an industrial panel pc standout among traditional HMIs is the robust computing power from low power multi-core processors and its local-data storage. The element of computing and the value from IoT data is unifying control system engineers to upgrade traditional HMIs to flexible panel pcs in order to consolidate complex automation workloads. What continues to drive the value of IoT is the logging and monitoring of data assets in real-time. Industrial Panel PCs have the capability to compute and store results locally on the device itself, creating a means for actionable insights. In a growing world of IoT connectivity and machine to machine communication Panel PCs continue to play a significant role for industrial control and automation.

Modular Industrial HMI Panel PCs

Premio's industrial touch display systems are patented and reliable products designed specifically for HMI automation, information and communication applications. The patented modular design makes the display system more flexible and versatile by providing a unique solution as both an industrial panel pc or a touch monitor. With robust hardware engineering and tested rugged features, our industrial touch displays can easily withstand a wide range of extreme environmental challenges.

Premio HMI solutions deliver a professional IP65 rates display solution with screen sizes ranging in popular automation sizes from 10.1" to 21.5" in both widescreen (16:9) and standard (4:3) aspect ratios. In addition, our industrial displays support the most common touch technologies including Projected Capacitive (PCAP) and Resistive. Learn more about Premio's Industrial All-in-One Panel PCs and Display Monitors below by checking out our VIO 100 / 200 Series.

IP66/69K Washdown Touchscreen HMI Computer

The stainless steel SIO Series are IP66- or IP69K-rated, both of which provide water protection against powerful waterjets from any direction. Compared to the IP66 rating, the IP69K offers premium protection against close-range high-pressure, high-temperature washdowns essential to sanitary assurance. Moreover, the SIO Series feature native touchscreen enable/disable controls, allowing the device to remain powered throughout intense washdowns. This design enables the SIO to maintain automation, monitoring and critical control functions. The SIO washdown stainless steel panel pcs are available in multiple screen sizes that can integrate smoothly into HMI automation infrastructure with ease. A selection of 21.5" or 15.6" 16:9 screens, and 15" or 12.1" 4:3 screens provides scalable options and software display compatibility for in-line HMI automation. 5-wire resistive single touch and multi-touch projected capacitive touch technologies are available to meet specific industrial applications. Above all, given the SIO’s remarkable suitability to hygienic environments, these panel pcs represent the ideal Industry 4.0 solution for food and beverage processing, pharmaceutical manufacturing, and cleanroom settings.

IP66 Stainless Steel Touchscreen HMI Computer

The IP66-rated enclosure of the WIO Series withstands aggressive exposure to water and pollutants in environments where these conditions are commonplace. Precisely, the enclosure of the WIO Series is dust tight and resistant to powerful water jets with a pressure of up to 100 kPa from any direction. IP66 protection shields hardware deployed to drenched and dusty conditions, or subject to frequent washdowns in rugged environments. Furthermore, the WIO Series are incredibly slim with 74mm thickness without compromising enclosure strength. The WIO Series serve as a powerful tool for reaping Industry 4.0 efficiencies in industries such as mining, agriculture, and livestock management.

Visit our 2020 Solutions Catalog to learn more about Premio products and services. Schedule a meeting with our solution experts at sales@premioinc.com or call us at 1-800-977-9646