Rolling stock computing systems are inherently complex and mission-critical, with railway signaling playing a lead role in moving freight and passenger trains safely around the rail network. Latency-free data handling is crucial, says Dustin Seetoo, director of product marketing, Premio, Inc. , with significant amounts of data transmitting reliably and efficiently between rail vehicles and railway control hubs.

These sophisticated traffic management systems keep rail cars a safe distance from one another, allow time for sufficient braking, and control rail operations that determine the position and safe path of trains. One railway leader recognised that smart upgrades to its railway signaling infrastructure could add next-gen performance to its other data-centric applications, such as real-time surveillance.

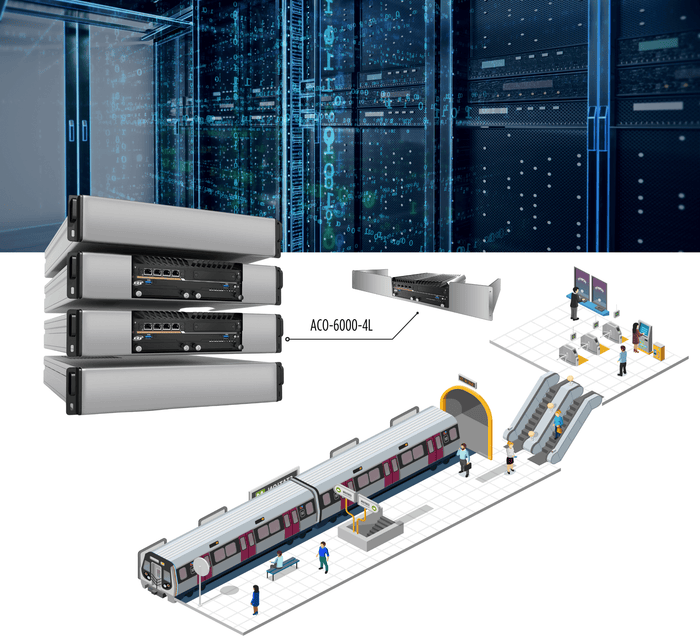

This railway provider had initially developed its own upgraded railway signaling system as a 2U 19-inch rackmount system designed for train-borne installation. Sourcing every component and certifying the system had taken 18 to 24 months further performance upgrades needed to be handled much more efficiently.

Additionally, the rail system provider desired a more modern approach to railway signaling, focusing more on handling data right at its source. A rugged-edge computing device that outperformed previous systems could improve other railway data centric applications, such as network video recorders (NVRs) used for real-time surveillance. In each scenario, ruggedness was imperative, handling critical data workloads with the temperamental rolling stock environment.

A building block approach would reduce design timelines and resources, quickly resulting in solutions that are standard, vetted and certified. Once its own final specifications were considered and integrated, the firm’s compute provider delivered a testable product within 30 days. The system was quickly and easily connected with the rolling stock’s block architecture network, allowing for rapid deployment with minimum downtime.

The backbone of this solution is an industrial grade computing system that is tested, pre-certified, and EN-50155/50121-3-2/EN50121-4 standards compliant. The railway firm’s compute provider also took on risk assessment and performance validation to ensure compliance with IS402, a safety regulation administered by the European Union Agency for Railways. The system’s modular design allowed tuning of its 4LAN port daughterboard module, meeting HIPOT certification based on factors such as surge assessment, dielectric withstand, and insulation and pulse resistance.

Supported by 6th and 7th Gen Intel Core processors, the solution delivers sophisticated CPU performance, power efficiency, and heightened connectivity for edge-to-cloud computing. Data workloads, now decentralised away from the cloud, are processed immediately, in real-time near their source an approach that is optimal for railway signaling operations and their mission-critical nature.

The solution’s workload consolidation is also ideal for the data transmissions relevant to IoT surveillance applications. Rugged NVRs meet EN50155 and EN50121-3-2 performance standards for temperature, humidity, shock, vibration and electromagnetic compatibility. The system operates as a true rugged device, merging performance with solid state storage, RAID-based data redundancy, and inference processing to create excellent visual processing and recording in harsh, physically demanding environments.

A significant differentiator is the system’s scalable support up to 16 PoE devices allow for strategic positioning of surveillance devices, helping optimise potentially limited power resources. Multiple cabins, with up to 16 cameras each, operate as a real-time surveillance network throughout the rolling stock environment. Data security is also a design priority the system utilises a trusted platform module (TPM) to secure data at the hardware level, protect against malware, and encrypt data to be compliant with privacy controls like the General Data Protection Regulation (GDPR).

Premio’s ACO-6000 series of in-vehicle computers is an industrial grade compute system reliability-tested and certified to IS402 and EN-50155/50121-3-2/EN50121-4 standards

This solution serves an important part of vehicle fleet management, establishing continuous wireless connectivity through Wi-Fi and 4G/LTE connections, fleet network connectivity through SIM module sockets, and integration with vehicle CAN bus processes. Critical and administrative data, like telematics, scheduling and rail conditions, are received and analysed simultaneously. A smart, low-maintenance system design protects vehicle downtime, eliminating potential points of failure to extend MTBF, and guaranteeing connections for all PoE ports by using an M12 locking connection.

Rugged-edge devices are advancing real-time decision making through advanced analysis, facial recognition, and object detection, improving service and safety in railway applications. Since June 2019, this railway leader has deployed this system more than 300 times, tapping into an intelligent building block design for competitive value and to get to market quickly. Rugged solutions for railway signaling and NVRs are movement towards instant insight by efficiently utilising extreme data processing close to its source no matter the environment.